Japanese Soakers

Bathtubs

Hot Tubs

Taps

Showers

Basins

Waste Overflow

Accessories

Get 10% off on any additional products

|

Aquatica AquateX™ White Material Sample

|

120.34 د.إ

|

Through extensive research and development, we challenged ourselves with a goal of creating a material with only the best qualities to use in our bathroom range. Our formulated composite results in superior quality and designer bathroom pieces, which can be crafted into practically any geometrical form and shape.

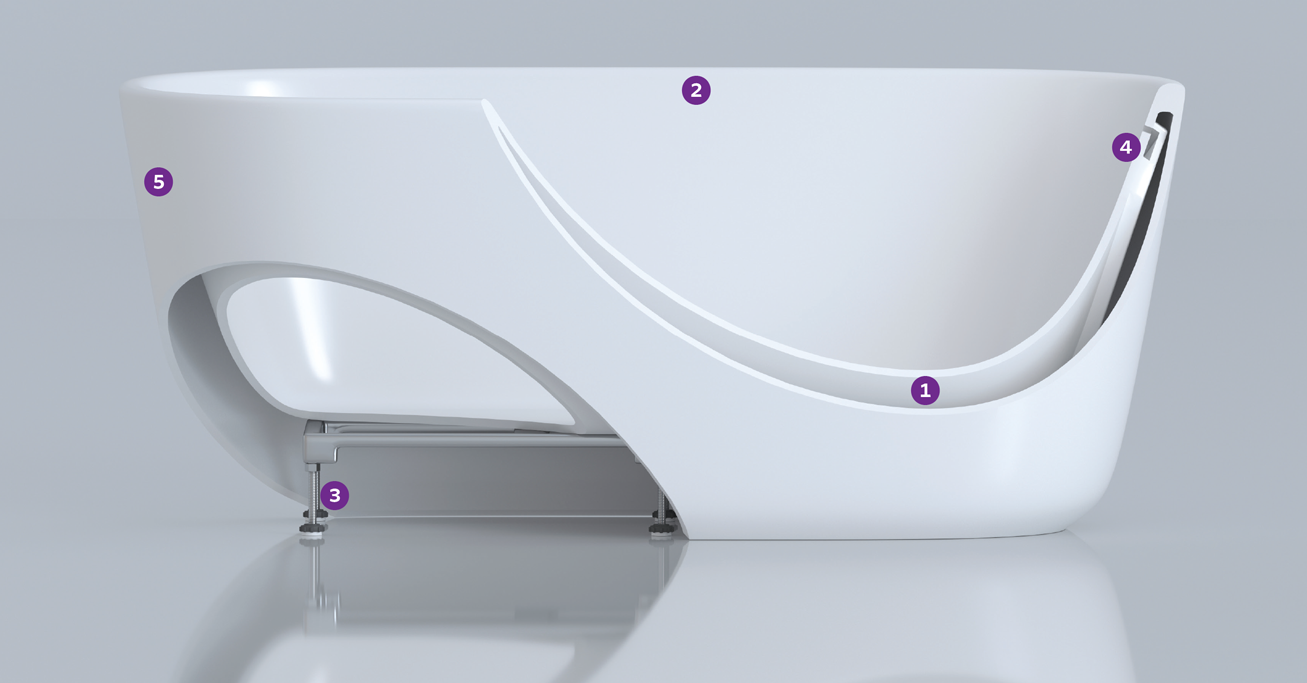

AquateX™ is a technologically advanced solid surface composite material, developed by Aquatica®.

60% of AquateX™ is composed of the aluminum mineral that is derived from bauxite, a deeply weathered volcanic rock. By combining a high percentage of all the best properties of natural materials; and a low percentage of state-of-the-art acrylic resins; we were able to create a desirable, high performance cast stone material that is specifically, suitable for high-end bathroom applications.

As a result, AquateX™ is an inert, hypoallergenic, non-toxic, 100% recyclable and fire-resistant stone composite material that combines two opposites - a warm, silky soft exterior and a tough, durable interior. It has a strong resistance to UV radiation, is dense/non-porous, hygienic, durable and is pleasant to touch due to its velvety texture.

In addition to all the excellent characteristics of our standard AquateX™, the AquateX™ LuX offers ultra-polished, glossy marble like surface for even easier cleaning and maintenance."

Any small signs of wear and accidental scratches can be easily removed using a common abrasive sponge, which will remove a tiny layer of the material surface, followed by surface polishing. This simple maintenance procedure will return the original gloss to the AquateX™ LuX surface.

Silky smooth texture, which is warm and pleasurable to touch. The closest reproduction of a natural stone surface, available in an elegant matte, or a glamorous polished finish, which has been specifically adapted for bathroom ware use.

If maintained properly, AquateX™ stone resin bathtubs and sinks will outlast most other materials. Any possible damage can be repaired by a specialized technician with little effort which keeps the AquateX™ bathtubs and washbasins looking new. AquateX™ is homogeneous throughout and will therefore never discolor.

AquateX™ is an innovatively ground-breaking and fully recyclable material.

AquateX™ can be used in areas with higher fire safety requirements. The surface won't lose its quality or properties, even at 100ºC. If an AquateX™ product is burnt - the material produces a liquid.

AquateX™ is an inert and non-toxic material, which is safe to use in medical facilities and can come into contact with food. It does not react to any chemicals being in its vicinity. Thanks to its composition and smooth seamless structure, it has inherent antimicrobial characteristics.

AquateX™ can be cleaned and restored to its original state with a simple abrasive detergent and a microfiber cloth, which can remove everything from cigarette burns, ink, hair dye, crayons, wine and coffee stains. Frequently cleaning an AquateX™ product will ensure the preservation of its original beauty. This will also prevent any wear and tear signs that might occur over the course of time.

AquateX™ is a UV stabilized and blush resistant material. It offers good resistance to UV rays and will undergo only nominal color changes under continuous exposure to water and sunlight.

Safe to use in medical facilities and in contact with food.

Unlike most other commercially available Solid Surfaces, AquateX™ is extremely resistant to yellowing or aging (the progressive color variation that the product undergoes over time). This is a very important difference which can be explained as follows.

This resistance to UV lightening is obtained at the molecular level by achieving the optimal molecular structure of the polymers. This innovative structure allows the material to retain its original colour even under prolonged exposure to sunlight or artificial UV light.

By contrast, the UV resistance of most other Solid Surface materials is achieved by solubilizing it with a mix of UV absorbing additives. These have a tendency to degrade over time due to the same UV radiation and therefore they protect the material from colour variations for only a very limited time.

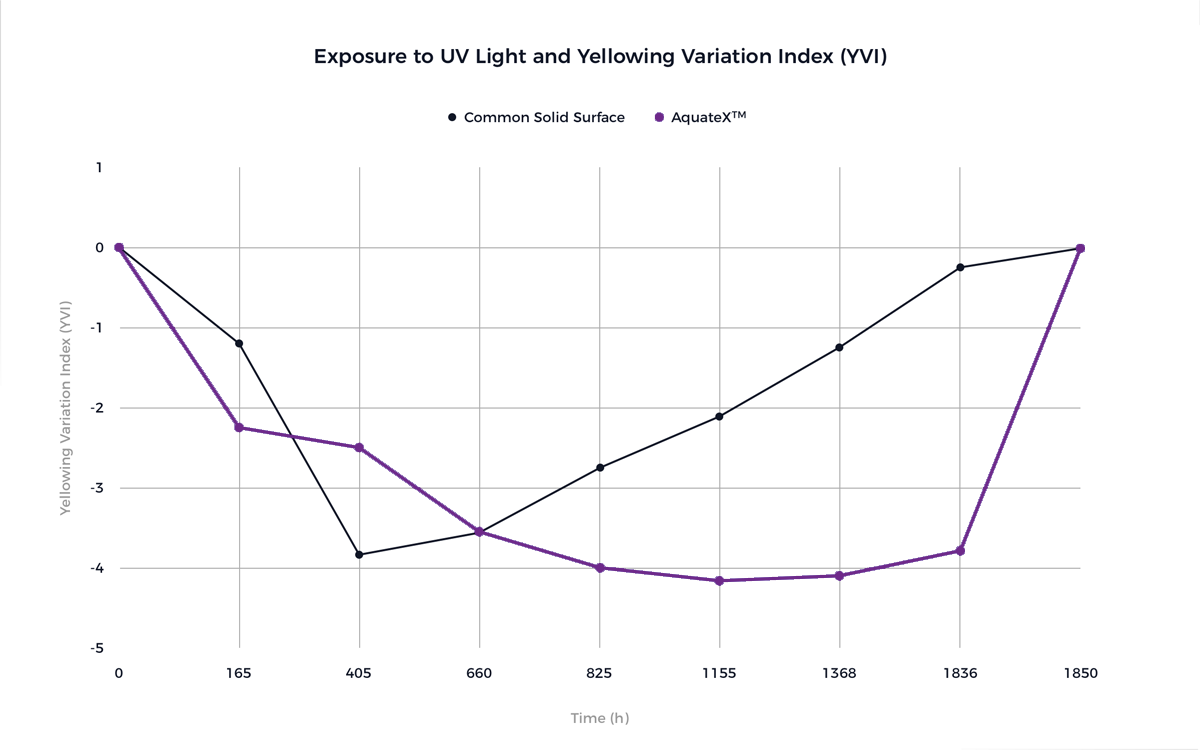

Our testing has been conducted using accelerated yellowing test methodology with UV type A lamps (similar to the solar spectrum), under temperature conditions up to 50°C and saturated water moisture.

The testing lasted for 1836 hours (76.5 days), an extremely long exposure time. It should be noted that in common solid surfaces the protecting effect of the UV-absorbing additives expires after about 405 hours upon which the material yellowing accelerates rapidly, quickly degrading its overall look and feel.

The graph shows how common solid surfaces, after just a couple of months, start becoming yellow and that this phenomenon accelerates over time.

AquateX™ after 77 days is less yellow than at the time of manufacturing, and this phenomenon will continue for many months, before its slow and imperceptible yellowing. The human eye perceives yellowing only when YVI ≥ 3 units.